Mass Based Products

Enersight 2.14 brings the capability to manage the inputs and outputs of Oil and NGLs on a mass basis rather than by volumes on an optional basis. This feature set is designed to provide localization of Enersight’s interfaces within Eastern Europe and will not be visible for general users unless enabled initially within Company Management, then applied on a per project basis.

Initial Configuration

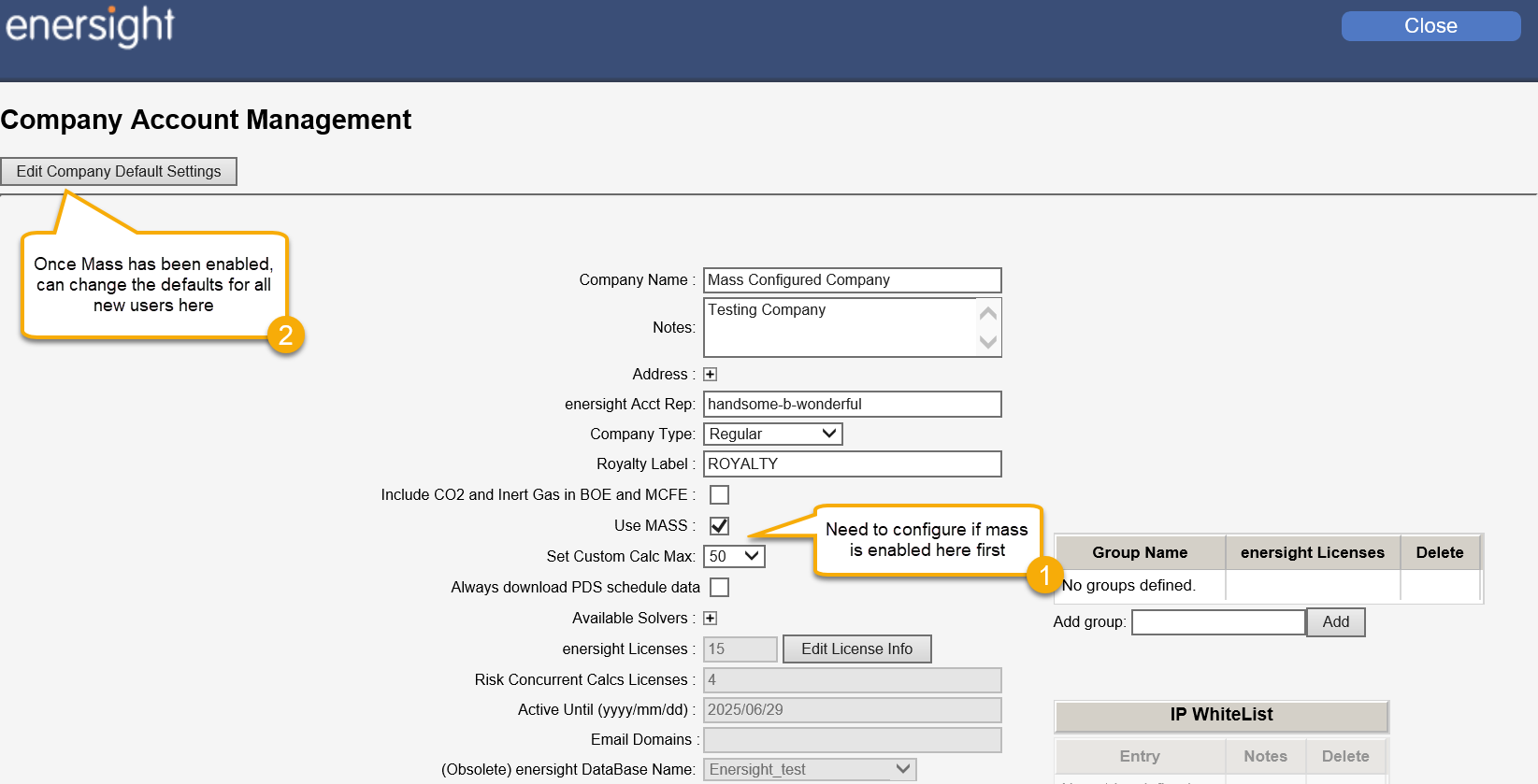

To create the initial configuration, Mass must first be enabled via Company Management.

Click image to expand or minimize.

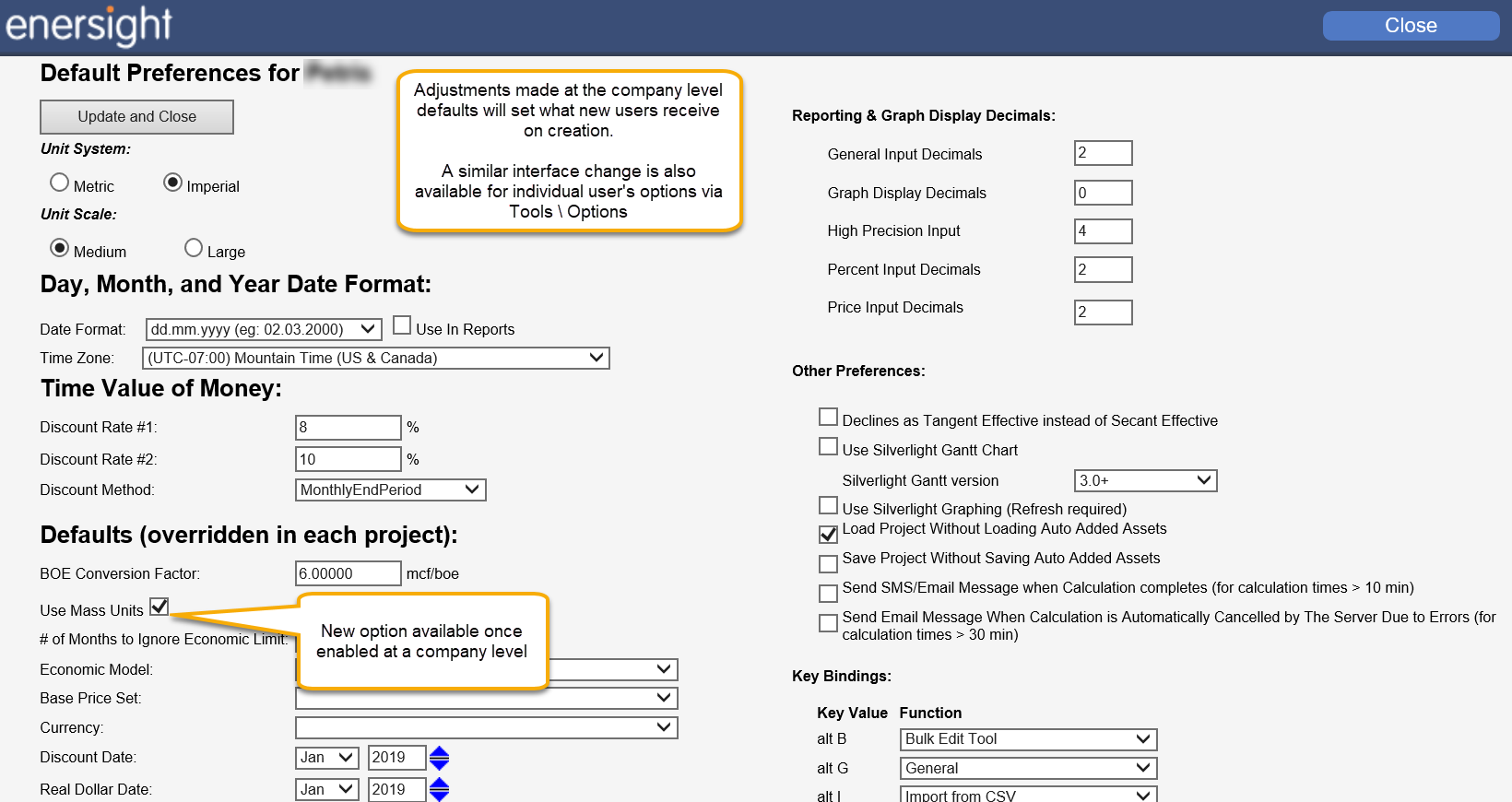

In cases where all users or all actions of a specific user are going to be associated with mass workflows, the default option may be specified at either a company or user level so that new projects created will have this setting automatically applied.

Click image to expand or minimize.

Alternatively, you could specify on a project by project basis via the Project tab to either apply it on applicable projects proactively to act as an override to the defaults if managing both normal and mass projects.

Click image to expand or minimize.

In Addition to enabling mass within the company and a project, you also need to configure the Mass type units via Administrator \ Units. Specifically:

- FluidMassRatio

- FluidPerMass

- GasMassRatio

- Mass

- MassFluidRatio

- MasGasRatio

- MassMassRatio

- MassPrice

- MassRate

- MassReserve

Please contact support@aucerna.com if you need assistance filling in these values.

Mandatory Changes to the Interface

Once a project has been configured to work within the mass paradigm, the following inputs are exclusively specified in mass using existing selection with just a change of units visible within the interface.

Production

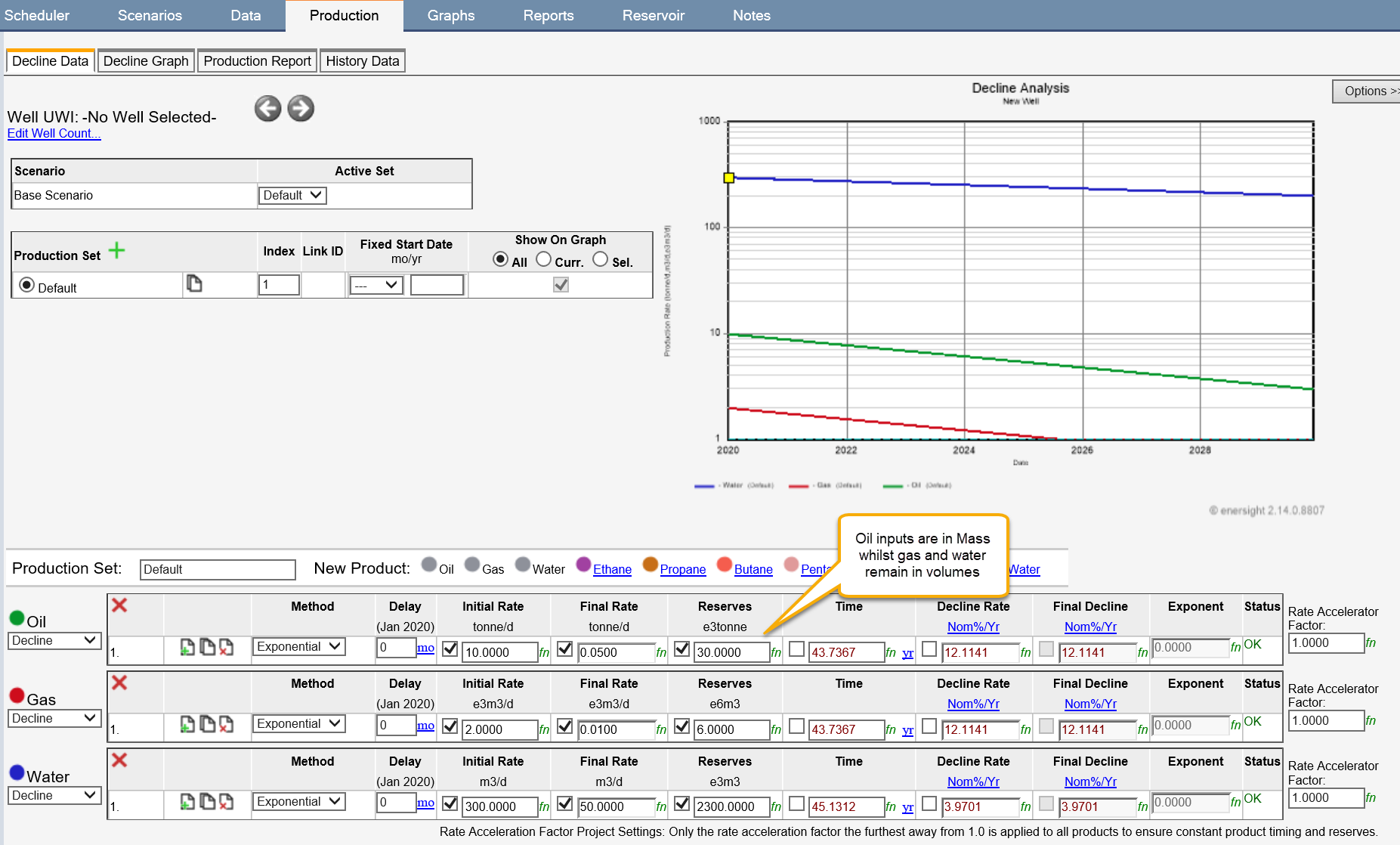

Changes to Production happen via either Decline/Prod, the Production Tab and/or the History inputs.

Within the Production tab, as per the example below, the inputs are now on a Mass or Tonne/d basis for oil (would similarly be applied to NGLs if entered directly at the well) while Gas and Water remain using volumetric units.

Click image to expand or minimize.

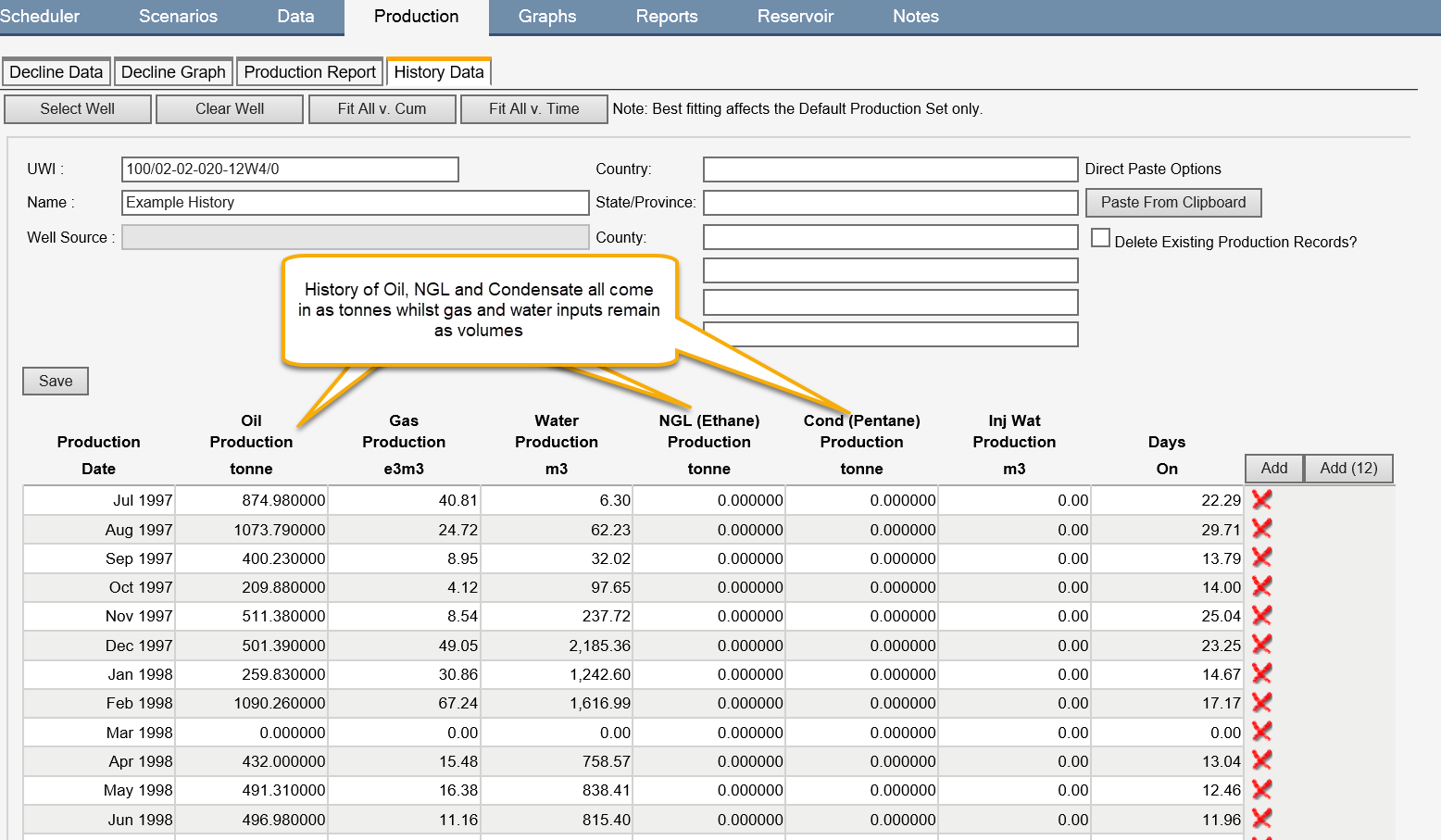

If you then looked at mapping the well to history data, the history management screen would display in mass units as the project has been configured to work in this manner. Selecting a well then brings in the data in those units.

Click image to expand or minimize.

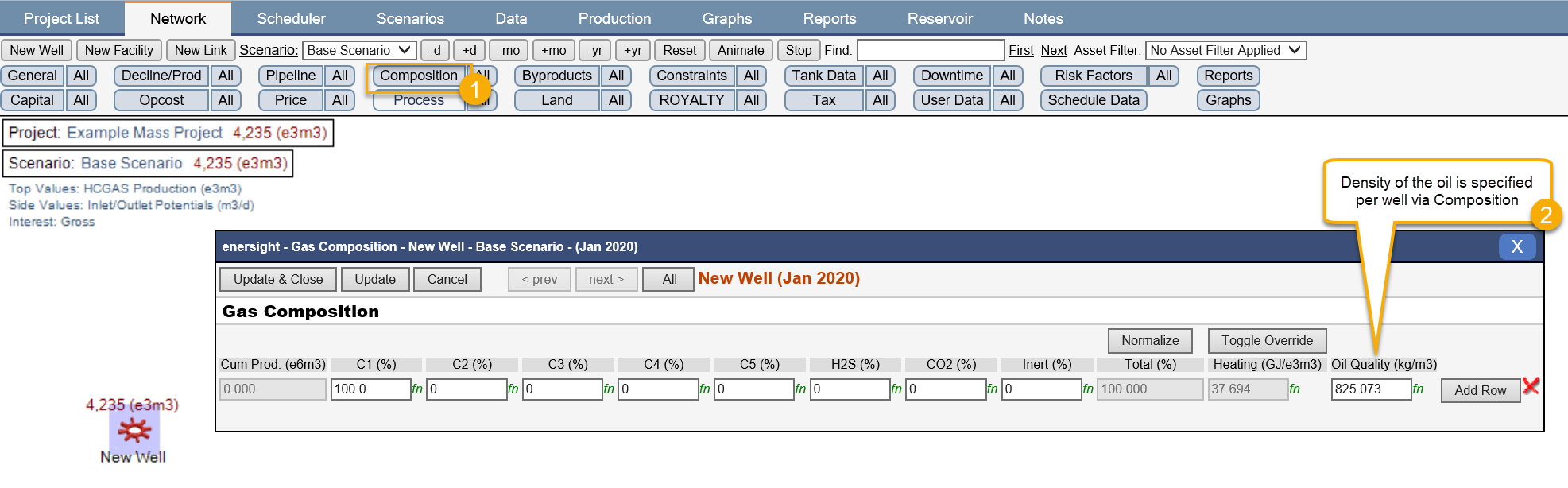

In addition to specifying the production rates, individual wells may also have differing quality levels as specified within the composition tab. You need to ensure that if manually inputting details within the interface, the correct density is specified prior to the production decline as otherwise the oil is scaled based upon relatively fixed volumes. Similarly, if uploading the data via CSV, the density needs to either be specified with the decline inputs or prior to.

Click image to expand or minimize.

Click image to expand or minimize.

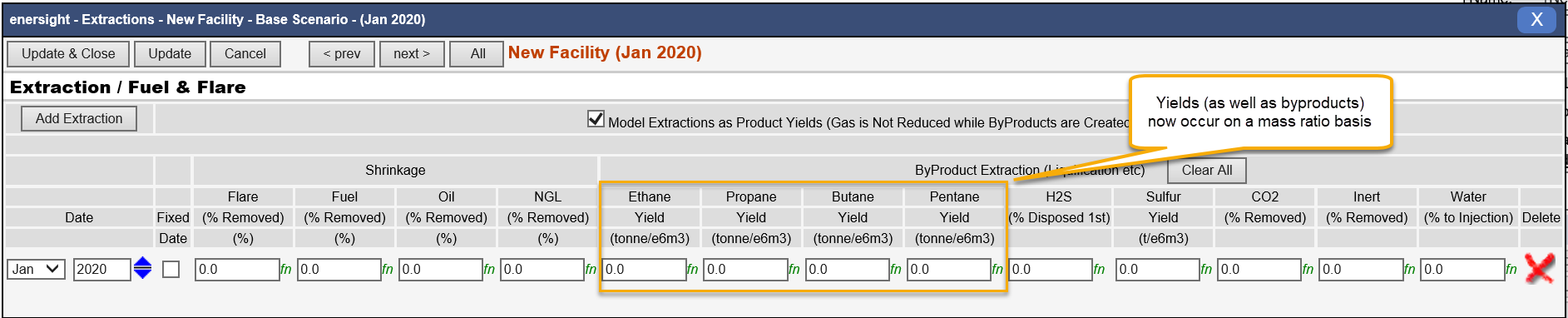

Byproducts and Yields

Both Byproducts and Yields are also automatically swapped to operate only on a mass basis post configuration of the Project as using Mass.

Click image to expand or minimize.

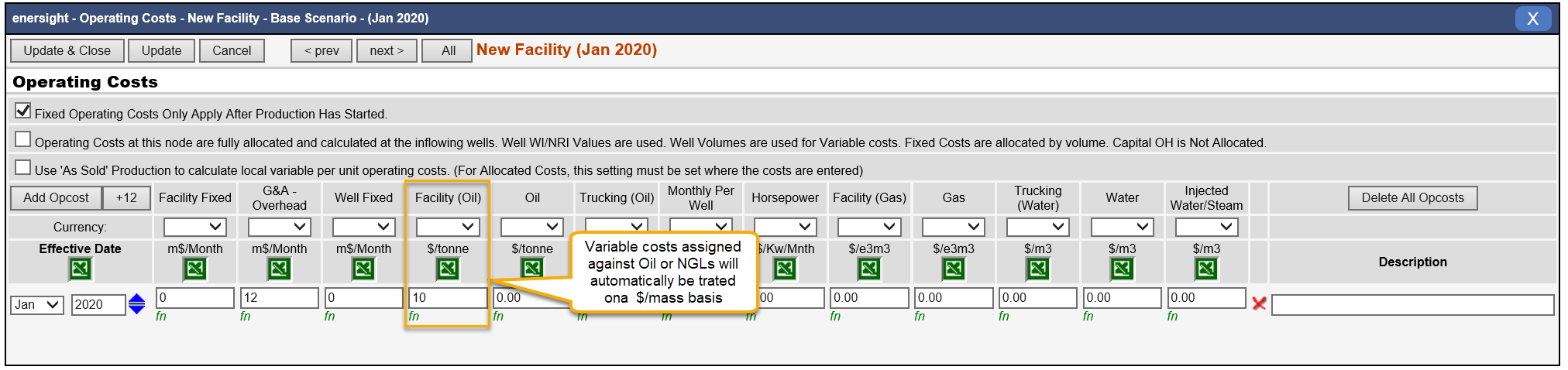

Operating Costs

The variable rate portion of operation costs are automatically swapped to only operate on a mass basis post configuration of the Project as using Mass.

Click image to expand or minimize.

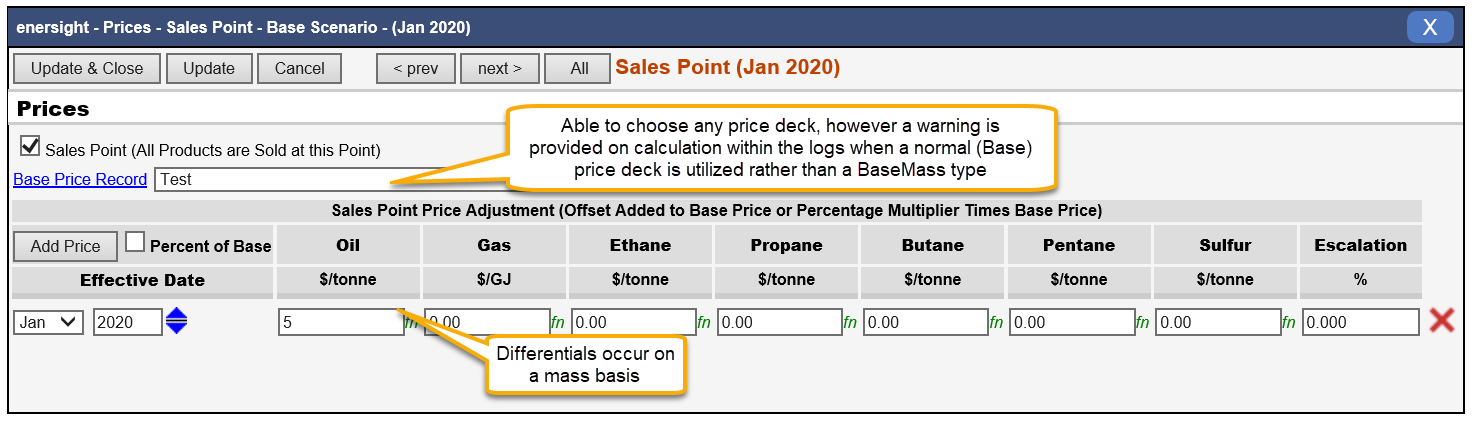

Prices

Price Sets have a new option where they can be defined as a BaseMass type – enabling input on a mass basis. For companies set to use mass, this is the default setting when creating new price types.

Click image to expand or minimize.

Once a Price Set has been created, it can then be selected at a sales point within the network. If BaseMass type price set is utilized on a non-mass project or if a volumetric Base type price set is utilized for a mass project then there will be a warning added to the calculation log to advise that it is likely the incorrect set has been selected.

Click image to expand or minimize.

Processing

The input of processing fees and revenues amounts are automatically swapped to only operate on a mass basis post configuration of the Project as using Mass.

Click image to expand or minimize.

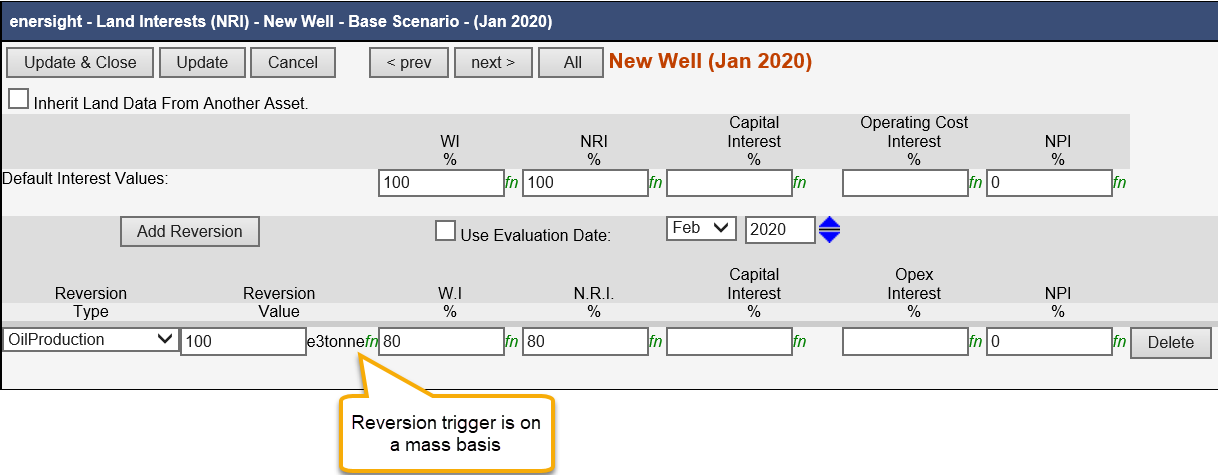

Land

Whilst the input of land details typically has little relationship with mass or volumes, the OilProduction reversion trigger is automatically swapped to only operate on a mass basis post configuration of the Project as using Mass.

Click image to expand or minimize.

Optional Changes to the Interface

Once a project has been configured to work within the mass paradigm, the following inputs are optionally specified in mass via the addition of extra options within the interface as alternative ‘product’ types for input.

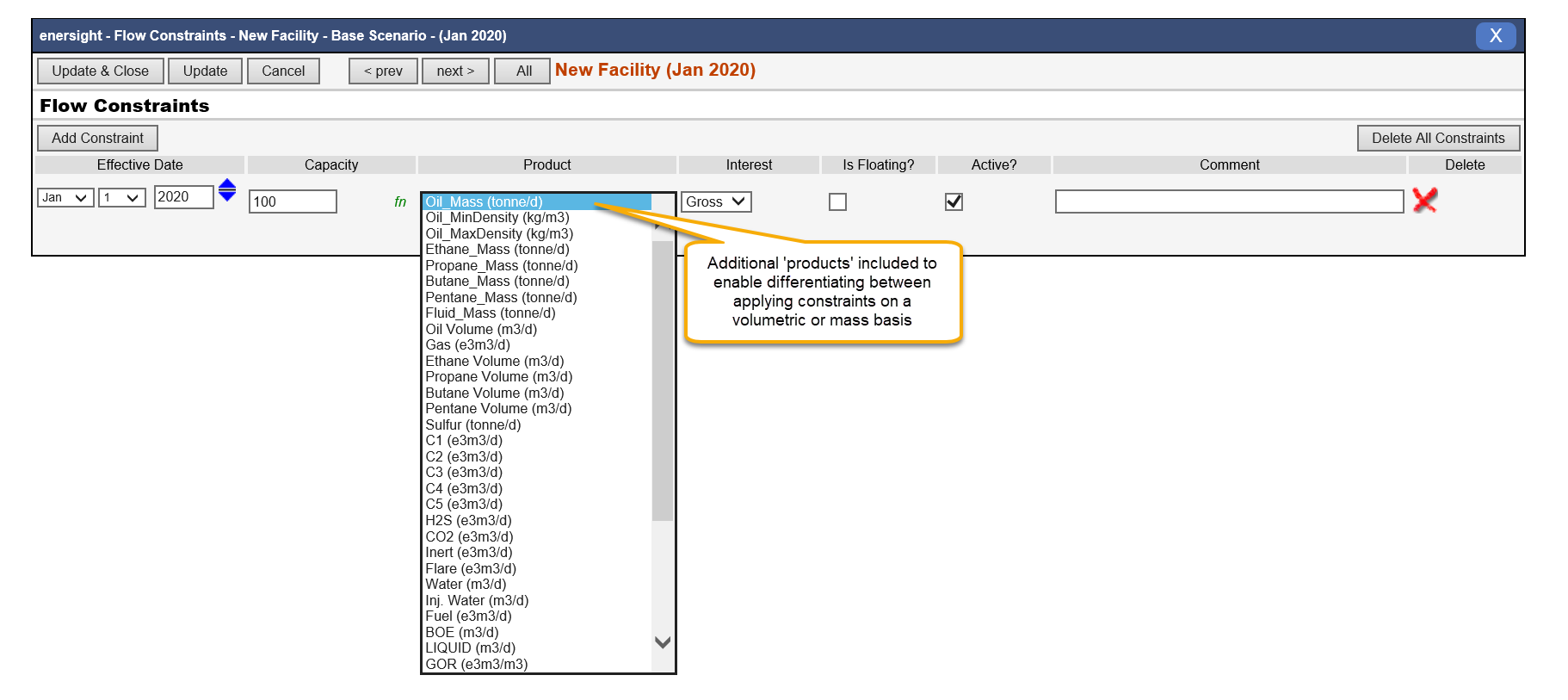

Constraints

Both volumetric and mass-based constraints can exist simultaneously within the model. This enables details such as positive displacement pumps to be treated on a volumetric basis while processing and sales may be at the nameplate or marketing demand requirements respectively. Where both mass and volumetric constraints exist on the same asset for the same product, the most restrictive constraint will be the determining factor in the available throughput. The mass constraints manifest themselves as additional ‘products’ within the application menu. Within simulations, the scheduling calculation elements of fill facility, sequencer and production threshold type scheduling conditions will work on a mass basis if that type of constraint is present on the target asset(s).

Click image to expand or minimize.

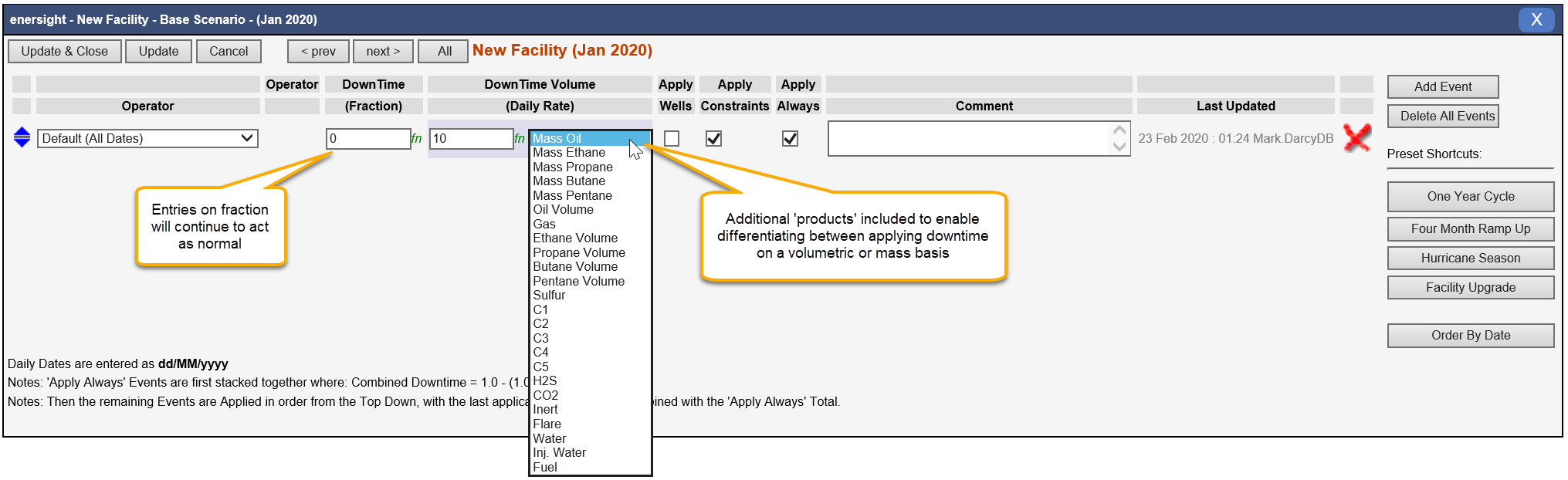

Downtime

Most downtime entries are typically done as Fractional inputs for which no change is required either on a calculation method or input basis. Where fixed volume downtime is utilized, there is an option to instead override this with a mass amount through the selection of one of the additional products.

Click image to expand or minimize.

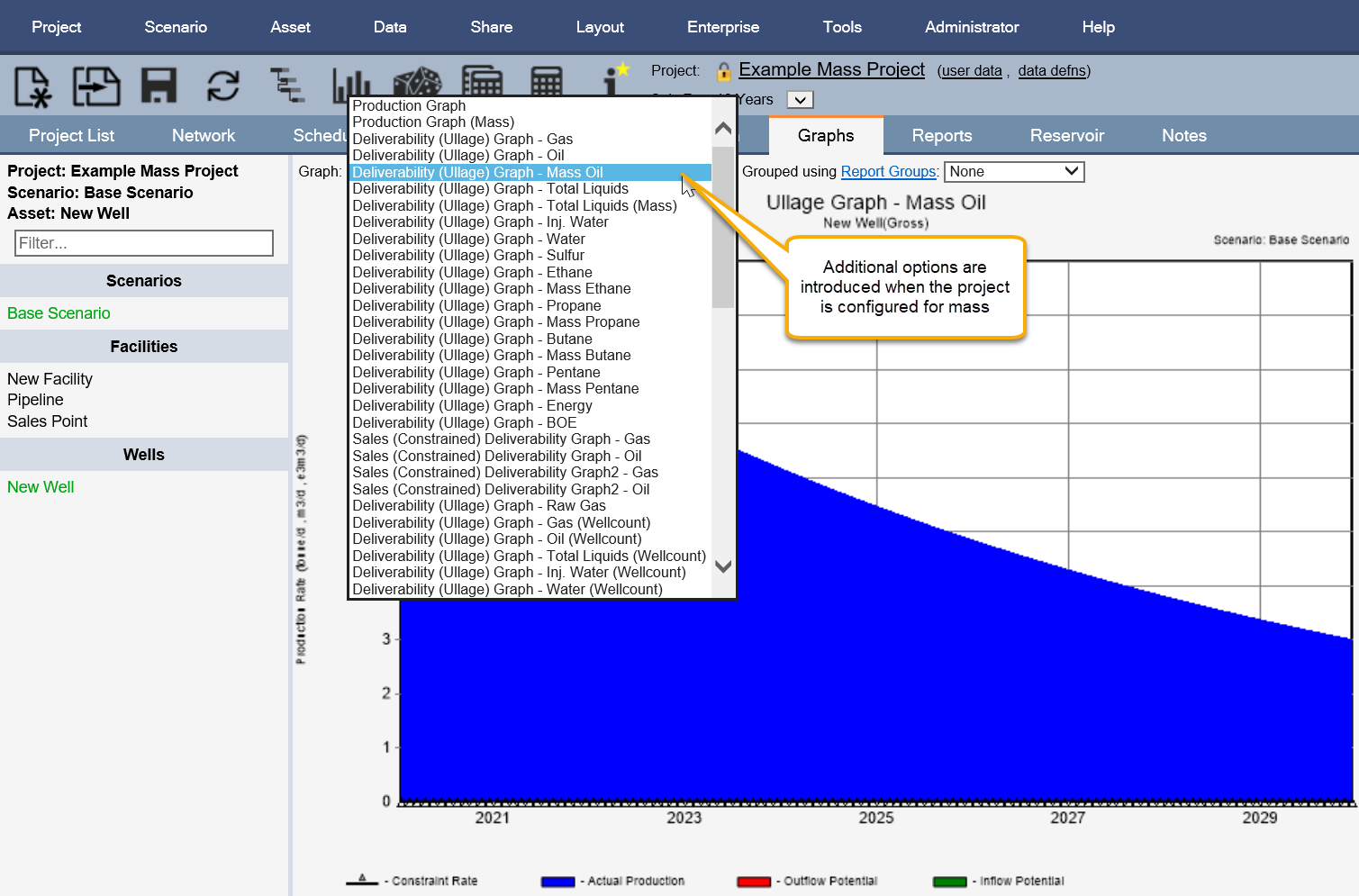

Results, Graphs and Reporting

The results from the simulation include both volumetric and mass-based outcomes, enabling a full suite of values to be generated for either purpose. Within the interface, the user will need to select alternative graph types in order to see the mass unit type results – aligning with the extra products as per the constraints and downtime.

Click image to expand or minimize.

From a reporting perspective, each production type column will need to be remapped to utilize alternative unit selections, typically Mass, Mass Rate or MassPrice. The Unit Label for each column will also need to be updated to reflect the changed selections. Please contact Quorum if you wish to access some pre-configured mass based reports.

Within the exports to PlanningSpace and Portfolio an extra checkbox will become visible to specify whether mass-based results are exported becomes available based upon company selection. OData exports will automatically be in mass if selected as applicable at the company level.